Thermoplastic Polyolefin (TPO) is a common sight in large commercial buildings. It’s one of today’s most popular commercial roofing options. TPO is known for its sustainability, strength, durability, and energy efficiency. This material has been around for decades and it remains the top option for commercial structures.

Keep on reading to learn more about TPO roofing systems and why people are continuing to choose them.

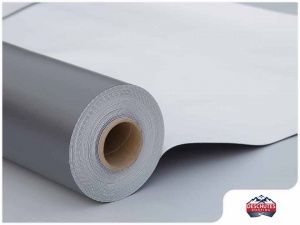

What Is TPO?

Among the fastest-growing commercial roofing systems is TPO. It is a single-ply roofing membrane that is composed of a single layer of synthetics and reinforcing scrim that can be used for flat roofs. This roofing option is typically a combination of polypropylene and ethylene-propylene rubber. They come in sheets that are 10, 12, 20 inches in width. They are then rolled up and brought to where it will be installed.

It features a naturally reflective surface that deflects the sun’s ultraviolet rays. TPO roofing systems create an effective barrier made to withstand water, snow, and ice. According to the National Roofing Contractors Association (NCRA), TPO makes up around 40 percent of the commercial roofing market share. However, it can also be used in residential roofing systems.

Moreover, TPO consists of three layers, which are the top, middle, and base. The top layer is formulated with UV blockers and abrasion-resistant compounds. Also called ‘scrim’, the encapsulated middle layer is a strong polyester mesh material that adds structure to the membrane while increasing its resistance against puncture and tensile strength. Then there is the base layer signed to improve strength, adhesion, and flexibility.

What Are the Benefits of TPO?

Cost-Effectiveness

TPO is more cost-effective than other rubber roofing options, such as EPDM. TPO has the same benefits as PVC roofing, like hot-air weldable seams and energy efficiency but at a reduced cost. Keep in mind that different factors come to play when it comes to the cost of installing a TPO roof, such as labor, the thickness of the membrane, the installation method, and the season when it will be installed.

Ease of Installation

Contractors have different options when it comes to the installation of TPO. It can be secured with adhesives or attached directly to the decking. Installers can heat-weld TPO around chimneys and other penetrations as well. Unlike some roofing options, TPO is less likely to corrode and break down when it touches other materials.

Low-Maintenance Option

TPO offers excellent resistance to algae and mildew growth and it does not need pressure washing. It withstands dirt accumulation, tears, and punctures. Keep in mind that with a roof that is strong and easy to care for, you can enjoy significant savings on repair and maintenance costs. This popular commercial roofing material resists damage from expansion and contraction. Because of its flexibility, TPO allows for a structure to move and settle, without sacrificing the performance of the roof.

Sustainability

Since TPO is usually white on top, it reflects UV rays and prevents heat from entering your indoor spaces. Due to this feature, your HVAC system does not need to work as hard to keep you comfortable, saving you on energy costs. The white reflective membrane of the material excels the Environmental Protection Agency’s ENERGY STAR®requirements. On the other hand, the gray, white, and tan-colored TPO is acknowledged by the Cool Roof Rating Council.

Another great benefit of TPO is its longevity. When properly installed and maintained, this material can last between two to three decades. Aside from being energy-efficient, TPO is also eco-friendly, which means that it can help reduce your carbon footprint. With TPO, your building’s energy efficiency will increase and utility costs while keeping its occupants comfortable.

Tips for a Successful TPO Roofing Installation

Your Roofer Should Follow the Manufacturer’s Instructions

An experienced commercial or residential roofing company knows how to install TPO roofing properly as instructed by the manufacturer. Before the installation starts, it would help to review these specifications and instructions. The instructions usually have essential information about installation, such as how much overlap is needed for a proper seal.

Check the Weather

The weather plays a crucial role in the success of your TPO roof installation. Low-temperature installation is possible with mechanically attached systems. However, the gluing of the details and perimeter walls will still need to be completed when the temperature is more than 40 degrees. You and your contractor must be extra careful when it comes to storing the material because it needs to remain dry. Roofing contractors would need to be more careful when installing TPO under low temperatures and high humidity to make sure that it welds properly. Prior to the actual installation, be sure to check the weather forecast.

Proper Substrate Installation

Whether you’re getting a new TPO or metal roofing system, proper preparation of the job site is essential. Your roofer should prepare the surface where the TPO will be installed before the actual work begins. They should remove debris on the roof, such as branches, rocks, and dirt. Holes and gaps in the substrate must be sealed to ensure the new roof is as smooth as possible.

Check for Issues

During and after installation, your contractor should check if they have installed the TPO membrane properly. They should especially pay attention to the vulnerable parts of your roof, such as seams because they are more prone to leaks, as well as T-joints where three sections of the membrane overlap. Any burned sections of the membrane should be repaired or replaced because they are more likely to develop punctures and they can’t also hold a strong weld.

Only work with a reliable contractor for your residential and commercial roofing needs. When looking for a roofer, make sure to do your research, read reviews, and ask for references. Choose a roofer with relevant experience and has proper licensing, insurance, and bonding.

At Deschutes Roofing, we specialize in tile, TPO, and metal roofing. Give us a call at (541) 241-5720 (Bend), (503) 967-9590 (Portland), (541) 246-6860 (Eugene), (503) 468-7663 (Lake Oswego), or (503) 928-8750 (Beaverton). You may also fill out our contact form to get a free estimate.